Product Description

- REFRACTORY CONCRETES

Refractory concretes are thermally untreated composite materials with a refractoriness of 1000°C and above.

They consist of refractory filler, binder as additives. - Refractory concretes

harden at normal or elevated temperatures and have limited shrinkage at the application temperature.

The basic requirement for refractory concretes is volume stability. - The most dangerous

property of concrete that can lead to collapse is shrinkage. The second requirement for refractory concretes is the strength of refractory concretes, which changes depending on

the temperature in the following way:

– When hardening takes place at relatively low temperatures, for example up to

300°C, the strength increases

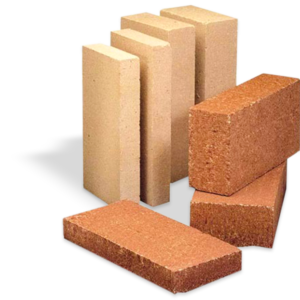

Refractory concrete ORBET-10 NC

APPLICATION:

It is used for the burner and the exit zone of rotary kilns in the cement industry, as well as for all places in industrial kilns exposed to high temperatures, abrasion, temperature changes and the action of alkalis.

INSTALLATION:

- Low cement refractory concrete is well mixed in a clean mixer. Mixing time in dry state is 1 min.

- The required addition of water is 5.13%, and it is recommended to add it all at once.

- Installation is done by vibrating. Larger areas must be divided into smaller fields of 0.8×0.8 m, where joints should also be foreseen. Templates are pre-cleaned, coated with template agent for better removal. The preparation time is 60-90 min., at an air temperature of +20(0C).

- At lower air temperatures, the preparation time is extended, and at higher temperatures, it is reduced. The bonding time until the coating is removed is 5-6 hours, depending on the thickness of the layer. Installation must not be carried out at temperatures below +5(0C). If installation is carried out on the remaining refractory wall, it must be moistened beforehand. Anchors must be coated beforehand.

- After bonding, air drying takes 24 hours. From 20(0C) to 120(0C) heat at a rate of 15(0C/h). Hold at 120(0C) for 5 hours or until evaporation stops. From 120(0C) to 300(0C) heat at a rate of 50(0C/h). Hold at 300(0C) for 4 hours. From 300(0C) to 550(0C) heat at a rate of 50(0C/h). Hold at 550(0C) for 4 hours. From 550(0C) to operating temperature heat at a rate of 50(0C/h). Keep at operating temperature for 4 hours and then cool slightly to 20(0C) and visually inspect.

Reviews

There are no reviews yet.