TECHNICAL CHARACTERISTICS

Compressive strength – MPa min65\

Flexural strength – Mpa min12

Abrasion resistance – 12cm3/50cm2

Ferobeton ORBET fer is certified at the Dr. Kemal Kapetanović Metallurgical Institute in Zenica

Ferrobeton ORBET fer is made in 3 basic shades: gray, green and red.

Other shades are made by agreement.

PURPOSE

Orbet fer Ferobeton is intended for the production of moderately loaded internal and external surfaces. Due to the possibility of choosing a color, it also has an aesthetic value. We recommend use in:

– garages and parking lots

– trading houses

– gas stations

– warehouses

– textile industry

– school corridors and workshops

– on sidewalks and ramps

– mechanical workshops for cars and trucks.

CHARACTERISTICS

Ferroconcrete consists of a mixture of Portland cement, quartz, additives and oxide colors. Concrete surfaces treated with ORBET FER ferroconcrete are:

– resistant to mechanical impacts and wear

– waterproof and resistant to weather conditions (frost)

– ne gore i ne korodiraju

– dustproof

– high wear resistance

– resistant to petroleum products and machine oil

– resistant to sea water and detergents

– anti-slip

INSTALLATION

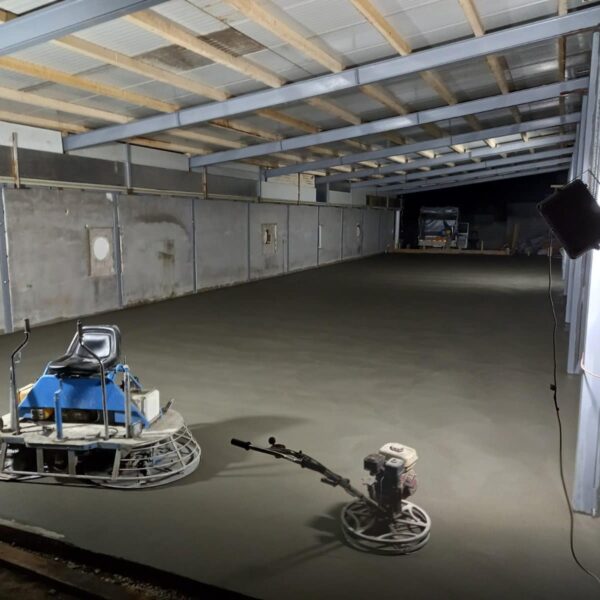

Orbet fer ferrobeton is sprinkled onto a fresh concrete base made of MB-30 grade construction concrete in the amount of 4 and 5 kg/m2 depending on the load of the future floor in two applications.

During the bonding process with a trowel machine (helicopter), we wedge (push) the ferrobeton into the base base. Before concreting the concrete base, we place metal bases that we level to the required plane and determine the slopes, lay reinforcement mesh and, if requested by the customer, PVC foil. All joints on walls, columns or foundations should be dilated with polystyrene strips.